OUR CORE SERVICES

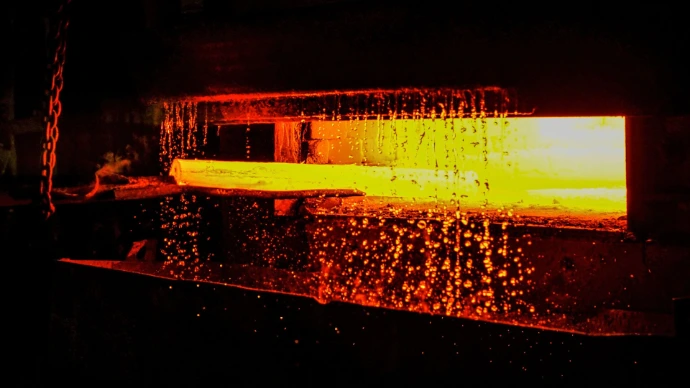

HARDENING TEMPERING-

It is a fundamental two-step sequence used primarily on steel to achieve the optimum balance of hardness, toughness for demanding applications.

Hardening makes the metal very hard but brittle , and tempering is the necessary follow-up process that reduces this brittleness while retaining most of the strength.

For Hardening, the steel is heated to a high temperature typically between 800°C - 900°C and held there and converted into a phase called austenite.

The steel is then rapidly cooled by immersing it in a quenching medium , such as oil, water or a polymer solution.

Outcomes-

•The rapid cooling prevents the carbon atoms from diffusing out of the crystal structure, transforming the soft austenite into a very hard, stressed and brittle structure called martensite.

•The steel is at its maximum hardness but also at its maximum brittleness. It contains severe internal stresses which make it highly prone to cracking or shattering under shock or impact.

Tempering is always performed immediately after hardening . it involves reheating hardened steel to a lower temperature , typically between 150°C-650°C,depending on the steel type and the desired final properties.

Then, steel is held at this specific temperature for a specific period of time ( soaking time). Then, It is usually cooled slowly in still air.

Outcomes-

•The lower reheating temperature allows the unstable martensite to decompose, relieving the internal stress and causing a very fine precipitation of carbides . This results in a new structure called Tempered Martensite.

• It increases toughness(resistance to impact ) , ductility(ability to deform without fracturing).

•Relieves the internal stress, making the components safe for service.

Normalizing

It is a process applied to steel to refine its grain structure , improve uniformity , and relieve internal stresses caused by processes like forging, rolling or casting .

•PROCESS-

It involves heating to a specific temperature for sufficient time. Then, material is held (soaked) at this temperature for sufficient time period to allow for complete transformation and homogenization. Then, material is removed from the furnace and cooled in still air at room temperature.

•OUTCOMES-

• The resulting microstructure is typically finer-grained ferrite and pearlite. This uniform grained structure is the source of improved properties.

•Normalizing improves the balance of strength, toughness and ductility, also effective in relieving internal stress.

Annealing

It is used to increase a material's ductility and reduce its hardness, making it more workable , formable and machinable. It also relieves internal stress.

•PROCESS- It involves heating to a specific temperature to ensure that the material is fully transformed into austenite. The material is held at this elevated temperature for a set amount of time to allow the internal structure to reach a state of equilibrium, relieves stress , and allow new, strain-free grains to form. The material is then cooled very slowly . This Slow cooling is the key difference from normalizing which results in the desired softness and high ductility.

•OUTCOMES-

•Reduces Hardness and Increases Ductility, Improves Machinability.

•Relieves Internal Stresses, Refine Microstructure.

Stress Relieving

If left untreated, these residual stresses can lead to dimensional instability (warping or distortion), potential cracking, and reduced service life or premature failure of the component.

•PROCESS-

The part is slowly heated to a temperature - typically 550°C-650°C for unalloyed and low-alloy steels . The material is then held at this temperature for sufficient time to ensure that the temperature is uniform throughout the part. During this phase, the elevated temperature lowers the material's yield strength .The part must be cooled very slowly in the furnace or in still air to room temperature. This slow cooling rate is crucial to prevent the reintroduction of new thermal stresses due to uneven contraction.

Gas Carburizing

Carburizing, or carburizing, is a thermochemical heat treatment process primarily used to create a hard, wear-resistant surface, or "case," on low-carbon steel parts while maintaining a tough, ductile "core." The process involves increasing the carbon content of the steel's surface layer to a sufficient level so that it can be subsequently hardened by quenching.

•PROCESS-

The process is applied to low carbon steels which are too soft to be hardened . The carbon atoms from the surrounding medium are adsorbed onto the steel's surface and then diffuse inward. This enrichment increases the carbon concentration of the surface layer (the case) to about 0.75% to 1.2%. The depth of this high-carbon layer (the case depth) is controlled by the temperature and the duration of the process. Once the desired case depth is achieved, the part is removed and rapidly cooled (quenched), typically in oil or water. The high-carbon case transforms into martensite, making the surface extremely hard and wear-resistant. The low-carbon core does not form hard martensite and remains soft and tough. A final low-temperature tempering step is usually performed to relieve quenching stresses in the case and improve overall toughness without significantly reducing the surface hardness.

•Advantages-

• Automation: The process is easily automated, making it suitable for high-volume, continuous production.

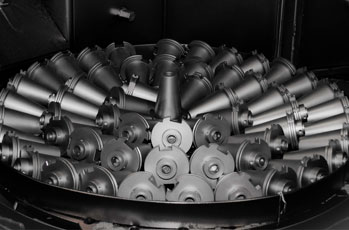

Shot Blasting

Shot blasting is a highly effective surface treatment method that involves propelling small, spherical abrasive particles (the "shot") at high velocity onto a surface. This forceful impact cleans, strengthens, or finishes the workpiece. It is a form of abrasive blasting, but it is typically distinguished from traditional sandblasting by the type of media used (spherical steel or cut wire shot instead of sand/grit) and the method of propulsion.

• When the high-velocity shot impacts the surface, the kinetic energy rapidly removes contaminants and alters the surface finish.

•ADVANTAGES- •Cleaning and De-scaling: Removing contaminants like rust, mill scale (oxidized flaky material from hot rolling), old paint, heat treatment scale, and chemical stains. This is crucial for maintaining the integrity and quality of metal parts.

•Surface Preparation: Creating a uniform, roughened surface profile (or anchor pattern) that significantly enhances the adhesion of subsequent coatings, paints, galvanizing, or powder coatings.